From Terry Springs Legacy to Central Springs: “Reviving Excellence in Every Spring”

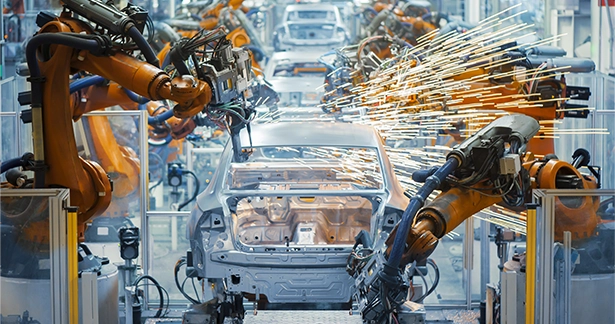

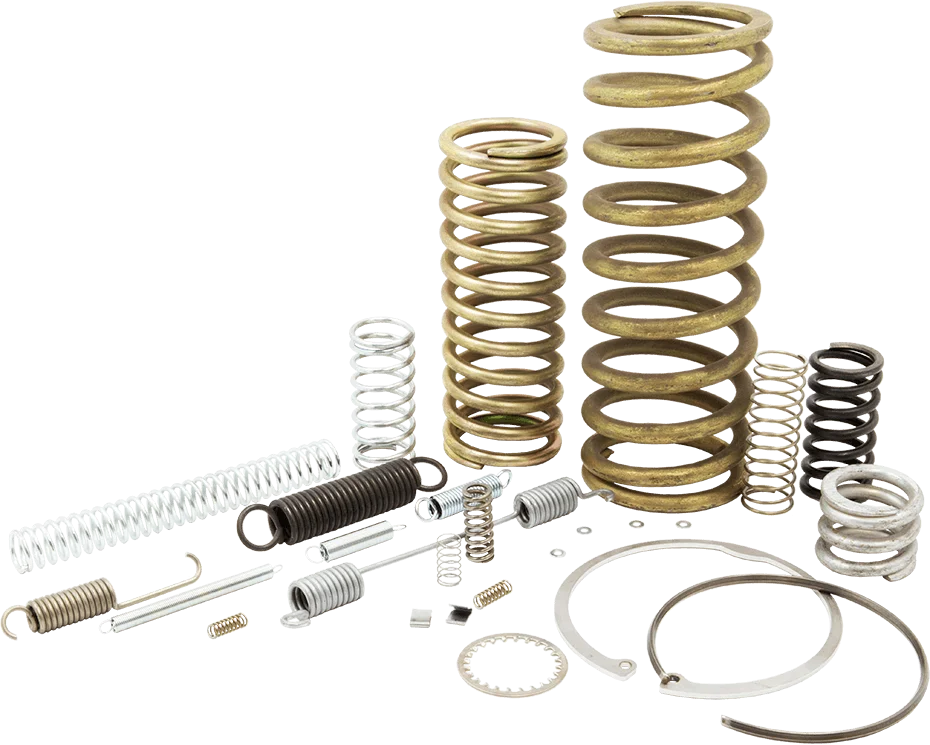

A traditional manufacturing company producing high-quality specialised springs and flat metal components for a variety of sectors including the aerospace, pharmaceutical, ministry of defense, and automotive industries.

Call us on 01527 514300 or find out more

From the Heart of Britain, Reaching out Globally

Central Springs and Pressing Limited, traces its roots back to Herbert Terry & Sons Ltd (Terrys) established in 1855. Once producing over 150 million spring components annually, Terrys was a European leader until the late 1960s.

The company faced challenges in the 1970s and 1980s but was revitalised in 1990 when Central Springs and Pressings' directors bought Terrys' Industrial Property Rights. Now, building on its heritage, the company thrives, innovating in spring components and aspiring for excellence in quality and service.

-

Quality

We are accredited to ISO 9001:2015, ISO

9002, and British Aerospace Quality Assurance.(BAc/AG/10400/CHD) (BAc/AG/30323/CHD).

-

Quick Turnaround

With materials readily available and priced competitively. We'll collaborate closely to ensure your project stays on schedule.

-

Low Cost

Our existing in-house tools serve various parts for cost efficiency. For custom tools, our experts ensure swift execution within your budget.

-

Innovation & Experience

We create bespoke tooling of the highest quality. Engage with us early to ensure your component is ideally tailored for its role.

-

Custom Tooling

Our on-site toolroom crafts top-quality bespoke tools for custom parts, be it in bulk or limited quantities. We tailor tools to your specifications.

-

Partnership

We take pride in our lasting customer relationships, thanks to our strong communication and dedication to ensure satisfaction.

Unbeatable Benefits

-

Quality

We are accredited to ISO 9001:2015, ISO

9002, and British Aerospace Quality Assurance.(BAc/AG/10400/CHD) (BAc/AG/30323/CHD).

-

Quick Turnaround

With materials readily available and priced competitively. We'll collaborate closely to ensure your project stays on schedule.

-

Low Cost

Our existing in-house tools serve various parts for cost efficiency. For custom tools, our experts ensure swift execution within your budget.

-

Innovation & Experience

We create bespoke tooling of the highest quality. Engage with us early to ensure your component is ideally tailored for its role.

-

Custom Tooling

Our on-site toolroom crafts top-quality bespoke tools for custom parts, be it in bulk or limited quantities. We tailor tools to your specifications.

-

Partnership

We take pride in our lasting customer relationships, thanks to our strong communication and dedication to ensure satisfaction.

No Project Too Big Or Too Small

We create components tailored to our client's specifications, so whether it's low or high volume parts, we possess the diverse manufacturing machinery to meet all your demands.

Our highly trained staff can produce limited numbers of components for pre-production runs, prototypes, and minute batches without the need for any tooling.

Moreover, we can produce large-scale batches using custom-made progression tools, which are both designed and crafted in our in-house tool room.

Need help? Ask us a Question

For more information or assistance, please call us on 01527 514300 or

email sales@terrysprings.com

With years of experience spanning back over a century and as a preferred choice from sectors such as defence, aerospace, pharmaceutical, and the automotive industry, we are the logical choice for custom springs, clips and pressings.